This was my first business trip back to China after returning home.

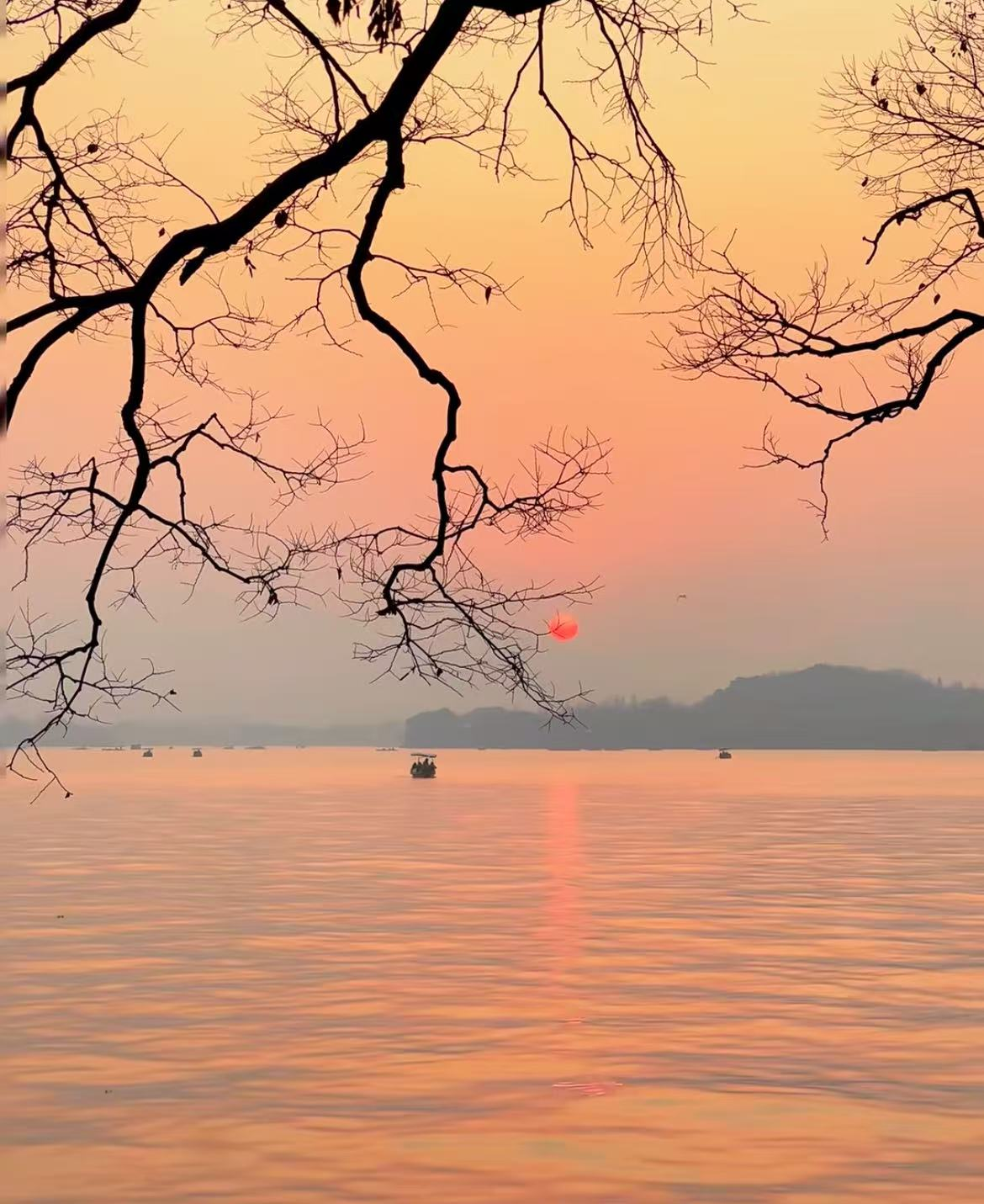

This afternoon, I arrived in Hangzhou, where I visited one of our long-term manufacturing partners. Sunlight filled the room as we sat down for tea before walking through the factory together — a moment that quietly reflects why factory visits in China remain essential in apparel manufacturing.

Inside the factory, what stood out most was not scale, but order. The production areas were clean, well-organized, and clearly structured. Each section followed a defined workflow, from material preparation to sewing and finishing. The production process was standardized, making it easy to understand how quality and efficiency are maintained on a daily basis.

These details matter. In custom sportswear manufacturing, a clean facility and a clear production flow are not just about appearance — they directly affect product consistency, delivery timelines, and quality control.

During our conversation, I also learned more about the founder behind the factory. Her fluent English was entirely self-taught. In the early stages of her business, as international customers began visiting, communication was not always easy. She started learning English on her own, using her phone and old textbooks, simply to better understand overseas clients and explain her products more clearly.

Her factory has grown in the same way she has — steadily and responsibly. There were no dramatic turning points, only continuous improvement: investing in better facilities, refining internal processes, and building a team that understands the importance of standards and accountability.

As the founder of Bizarre Sports, a custom sportswear manufacturer in China, I value these visits deeply. Seeing the factory environment, production systems, and workflow management in person allows us to ensure that our partners share the same commitment to cleanliness, structure, and reliability.

Factory visits are never just about checking machines. They are about understanding how people work, how processes are followed, and whether a manufacturing partner can truly support long-term cooperation with global brands.

This China business trip was worth every step.